Sequenced changeover of all process control parameters yields successful implementation of system upgrade with minimal downtime

Lisle, Illinois – Synergy Systems, Inc., a consulting engineering firm and Recognized System Integrator for Rockwell Automation, today announced the completion of a successful upgrade on the main blast furnace and stove control system at a major Midwest steel producer. Unique to this 18-month project was the absence of production downtime experienced by the client, during the transition from legacy control system elements to a Rockwell Automation ControlLogix and Wonderware-based HMI platform. Synergy Systems termed its protocol on this project the System Transition Execution Plan (STEP). During the implementation of STEP, the client experienced no interruption in overall blast furnace or stove control system operations, as it transitioned from an older DCS (distributed control system) to the new system, which was entirely designed and installed by Synergy Systems engineers, working onsite at the steel mill with client personnel.

At the heart of the concept, according to Synergy Systems VP Marc L. Hunter, “We developed our strategy around a core principle that targeted zero downtime during the changeover. Essentially, we created a building block operation, in which each control input/output on the old system was upgraded with parallel monitoring of performance values and system readouts. Only when each new component was functioning properly and the signals were inline with the existing monitored values did we execute the changeover of the control strategies, which was then integrated loop-by-loop into the new process LAN.” Utilizing this strategy, Synergy Systems enabled the client to maintain full production at the mill, throughout the entire project. Client engineering confirmed their complete satisfaction with the performance on this major project.

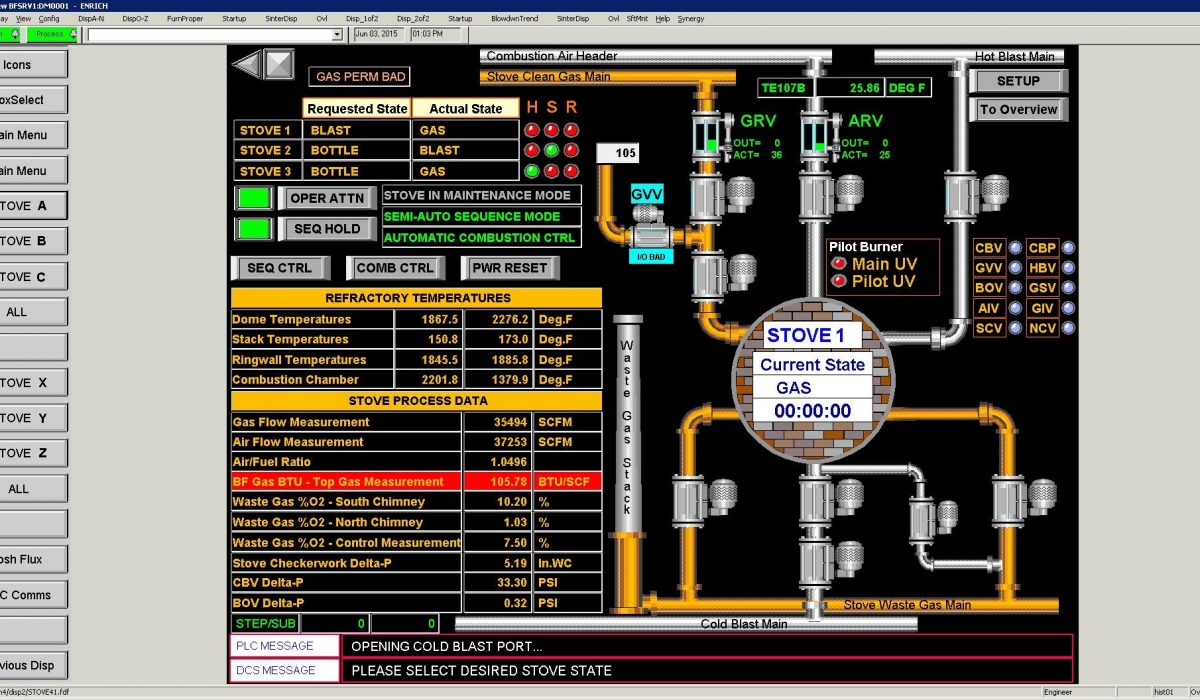

The STEP upgrades included all the following procedures: replacement of legacy PLC hardware with AB ControlLogix, replacement of DCS/PLC interface, movement of I/O from DCS to ControlLogix, deployment of Wonderware HMI, movement of control from DCS to ControlLogix, Wonderware historian integration and finally Level 2 interface via Wonderware HMI. Essentially, the control scheme for each system element was installed in parallel to the legacy control, then connected to the new ControlLogix processor and monitored on a channel of the client’s overall process control LAN for comparison to the older output.

Using this STEP approach, minimal process impact occurred and there was a significant savings realized for the client, both in operational expense and total project cost. As Hunter explains, “This project, because it happened in steps, so to speak, could be costed as a maintenance, not a capital, expense. The major capital expenditure diminished, owing to our strategy of loop-by-loop cutover and a gradual evolution of the graphical user interface, plus a progressive integration with the plant historian software. Collateral benefits to the client included a gradual weaning away from the legacy system, which allowed our team to thoroughly familiarize our client’s operational and maintenance personnel with the new hardware and software, as the changeover progressed.”

The determination to upgrade this system had resulted from numerous factors, according to the client. The I/O had become obsolete and the legacy system was UNIX-based, so many of the client’s current engineering staff onsite were not familiar with it. However, because a need existed to retain overall control strategies and functional client knowledge of system operations, Synergy Systems devised this STEP protocol to make the transition more gradual and self-teaching.

According to the client’s plant production & technologies manager on the project, “The blast furnace and stove control systems needed to be upgraded from a legacy DCS (Distributed Control System) to a Rockwell Automation PLC (Programmable Logic Controller) platform, with Schneider Electric Software Wonderware human machine interface and historian, along with statistical reporting mechanisms. Synergy Systems was challenged with cost-effective project deliverables requiring a proven transition plan, zero production outages, minimal risk implementation with no impact to production or product quality, improved technology with future expansion capabilities, improved process controls, enhanced operator interface, significant improvements to system reliability and stringent budgetary guidelines. This project required verification and movement of nearly 2000 I/O points, installation of new workstations, network communication upgrades, development of over 60 HMI screens with built-in diagnostics and alarms, extensive PLC programming, system functional documentation development and drawing approval, historian upgrades and onsite training. Finally, total project implementation and completion were required within a two-year period.”

He continued, “Synergy delivered beyond our expectations on every challenge presented. The innovative approach, level of engineering delivered and tools selected ensured a successful transition without impact to our production or product quality. Synergy’s professional manner plus their willingness to listen and offer solutions always made it easy for our Operations and Automation team personnel to work with them. The upgraded control systems have been in operation for nearly a year now, with high levels of reliability and efficient operations realized. Synergy proved to be an extremely cost-effective yet resourceful company, with a focus on the future of our mill control requirements. Our plant now has the technology to further enhance the automation strategies and drive flexibility and productivity that were not available with the legacy automation platform.”