Recently, with the help of a consulting engineering firm and system integrator, a major Midwest steel producer successfully upgraded the main blast furnace and stove control system with no interruption in overall blast furnace or stove control system operations. The challenge was to create a transition plan and minimal-risk implementation (with no impact to production or product quality) with zero production outages, improved technology with future expansion capabilities, improved process controls, enhanced operator interface, significant improvements to system reliability, and stringent budgetary guidelines.

The determination to upgrade this system came from numerous factors. The input/output components were obsolete, making it more and more difficult to stock parts and find replacement units. The legacy system was UNIX based, so many members of the current on-site engineering staff were not familiar with it. Because the plant had to maintain continual operations levels, as well as to retain overall control strategies and functional knowledge of system operations, a custom system was devised to make the transition gradual and “self-teaching.” This protocol was termed the system transition execution plan (STEP).

The STEP protocol allows for a gradual transition and an opportunity for self-teaching along the way. At the heart of the concept is a strategy developed around a core principle of zero downtime during the changeover. Essentially, a building block operation was created in which each control input/output on the old system was upgraded with parallel monitoring of performance values and system readouts. The changeover of the control strategies occurred only when each new component was functioning properly and the signals were in line with the existing monitored values. This was then integrated loop by loop into the new process local area network.

All of that was performed in a phased approach, section by section, over 18 months. The plant benefited, because through the gradual weaning from the legacy system, the plant’s operational and maintenance personnel could become thoroughly familiar with the new hardware and software systems.

The STEP protocol allows for a gradual transition and an opportunity for self-teaching along the way. At the heart of the concept is a strategy developed around a core principle of zero downtime during the changeover.

Another crucial dimension of migrating and integrating new controls for this project was to solicit and receive “constant operator input.” The nuances of the entire manufacturing process are both critical to future plant operations and are second nature for the operators who have worked in the plant for the past 30 years. So all the things operators do throughout the process are captured and programmed into the new automation. Integrator engineers worked with seasoned blast furnace operators on every step in the process. As a result, the new system was entirely designed and installed working on site at the steel mill with plant personnel.

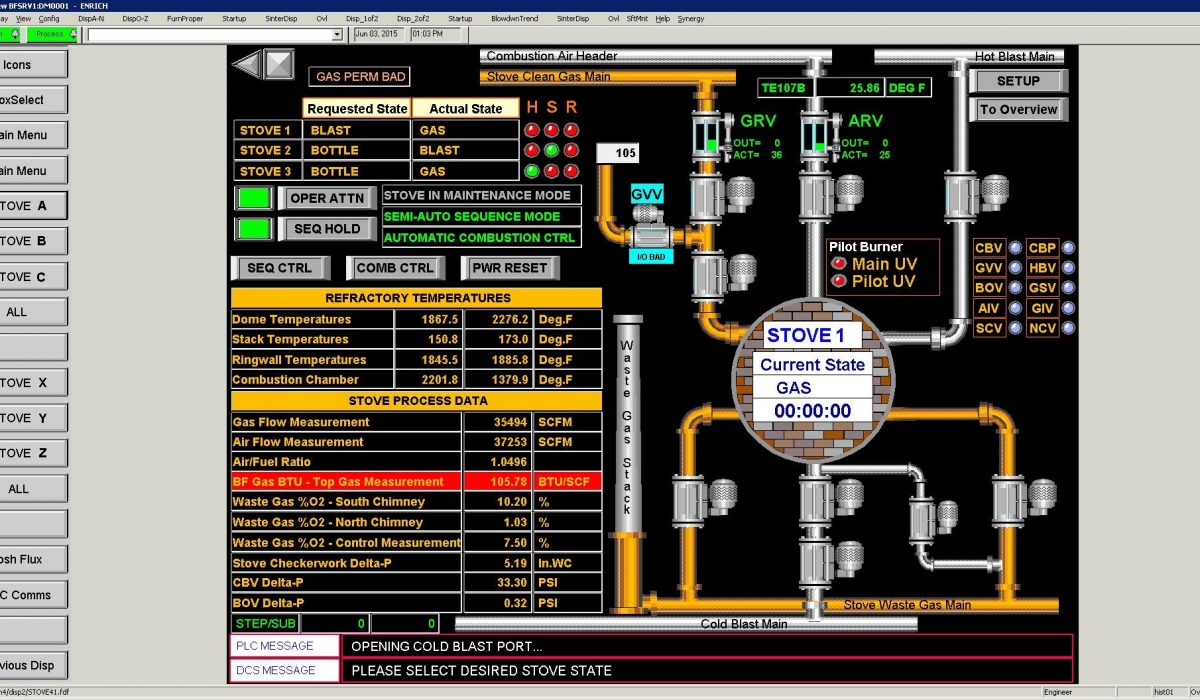

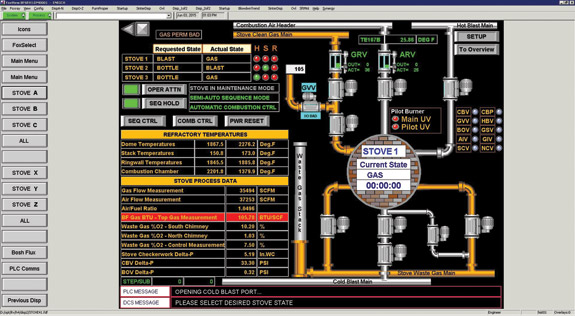

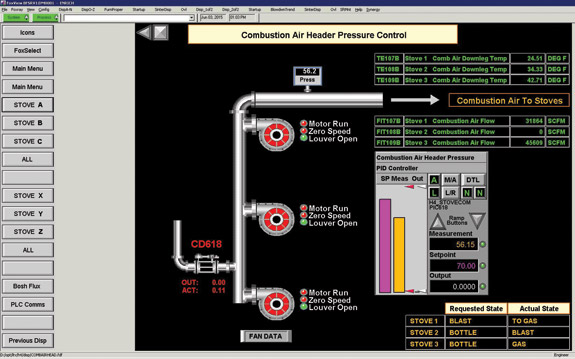

This project required verification and movement of nearly 2,000 I/O points, installation of new workstations, network communication upgrades, development of more than 60 human-machine interface screens with built-in diagnostics and alarms, extensive programmable logic controller programming, system functional documentation development and drawing approval, historian upgrades, and on-site training.

One reason the automation vendor felt the process worked so smoothly was there were very few bugs. When bugs did come up, the systemized process facilitated working with operational and technical support to fix them immediately.

Using the STEP approach, not only was the manufacturing process minimally affected, but the plant realized significant financial savings, both in operational expense and total project cost. Because this project happened in steps, it could be charged as a maintenance expense and billed monthly. The plant did not need to seek approval for a major capital expenditure.

The plant now has the technology to further enhance its automation strategies and drive flexibility and productivity in ways that were not available with the legacy automation platform. Engineering confirmed its complete satisfaction with the outcome of this major project and is looking to repeating the process on a second blast furnace when demand for steel picks up.

This project required verification and movement of nearly 2,000 input/output points, installation of new workstations, network communication upgrades, development of 60-plus human-machine interface (HMI) screens with built-in diagnostics and alarms, extensive programming of programmable logic controllers, system functional documentation development and drawing approval, historian upgrades and onsite training. All of that was performed—section by section, month by month—by Synergy Systems engineers working with seasoned blast furnace operators, says Marc L. Hunter, vice president-sales and marketing.

This project required verification and movement of nearly 2,000 input/output points, installation of new workstations, network communication upgrades, development of 60-plus human-machine interface (HMI) screens with built-in diagnostics and alarms, extensive programming of programmable logic controllers, system functional documentation development and drawing approval, historian upgrades and onsite training. All of that was performed—section by section, month by month—by Synergy Systems engineers working with seasoned blast furnace operators, says Marc L. Hunter, vice president-sales and marketing. The legacy and new control screens were designed for a similar look and feel, which allowed implementation requiring a minimal learning curve.

The legacy and new control screens were designed for a similar look and feel, which allowed implementation requiring a minimal learning curve.

You don’t have to be physically big to be one of

You don’t have to be physically big to be one of